|

|

Principal Products

- AIRTEK

- CENTEC

- DITECO

- DOSCH

- H E - TITAN

- HOFFER Turbine Flowmeter

- IGS

- INOXCVA

- MASTER MAG

- PHE- GEA

- SAIMO

- SODERN

- SYSCO

- TECTRON

- Thermofisher Scientific

SODERN

Full elemental analysis and non coal specific

Unlike other elemental analyzers that use PGNA (Prompt Gamma Neutron Activation) analysis exclusively, the SODERN CNA is “full elemental”. It is the only analyzer that directly measures all major elements (up to 14) including Carbon, Oxygen and Hydrogen which determines a reliable Calorific Value without prior knowledge of coal type.

Cutting edge PFTNA Analysis

SODERN is world known for its state of the art technology, especially concerning the PFTNA (Pulsed Fast & Thermal Neutron Activation) analysis, recognized as the most sophisticated technology available today for on-line bulk material analysis and control. It makes the SODERN CNA unaffected by varying belt loading, density changes or changing blend ratios from multiple coals. Long-life Comprehensive in-factory calibration is maintained over time as the neutron flux output is fully controlled, remains constant and never changes with SAP System.

Stable Analytical Performance (SAP) System

Using a neutron source continuously controlled and stabilized electrically, guarantees maintaining the same level of performance over time. Moreover, this technology makes periodic and laborious on-site recalibration no longer necessary.

NEUTRON ELEMENTAL ANALYSIS

In the mining industry, the elemental analysis of raw materials is a key step in the manufacturing process, for which quality, optimisation and profitability are primordial requirements.

SODERN's technology makes it possible to do away with artificial isotopic sources (Cf252 or Am-Be), which are still widely used even though they have been classed as "highly toxic" radionucleides by European regulations, and which pose an additional hazard as they are impossible to extinguish.

The generation of neutrons in a tube is based on the interaction between deuterium and tritium ions, which mainly creates neutrons with a kinetic energy of 14 MeV.

The use of a pulsed source makes it possible to apply a more advanced analytical method called PFTNA (Pulsed Fast and Thermal Neutron Activation).

This method consists in bombarding the raw material with pulsed neutrons, then measuring the energy of the gamma rays induced by the interaction of the neutrons with the nuclei of the atoms. Most of the elements composing the raw material are identified and immediately quantified.

This technology presents numerous advantages in terms of analytical performance, as well as environmental and operator safety.

The use of an electrical neutron source guarantees the stability of the system's analytical performance, through the constant production of neutrons throughout its life cycle. This characteristic reduces the number of periodic calibration operations, which are often difficult to carry out on-site and are always detrimental to production.

Moreover, with its On/Off function, the electrical neutron source can be handled without risk and can easily be transported by air as an excepted package, stored as a spare part and replaced whenever necessary without interrupting the production process.

CEMENT ANALYSER

Unlike conventional analysers which use a continuous-emission isotopic source, the on-line analyser made by SODERN – the CNA (Controlled Neutron Analyser) – uses an electrical neutron source with stabilised emission and can be switched off at any time.

The Cement CNA is installed at source between the first crusher and the pre-homogenisation stockpile, or before the raw mill for the blending of raw mix. Controlling the raw materials makes it possible to optimise the composition of the mix before the kiln operations.

The Cement CNA directly contributes to:

· extending quarry life

· removing the need for a sampling tower, which is often very expensive to maintain

· reducing the use of additives

· improving the the energy performance of the kiln

· extending the life of the fire bricks

· reducing CO2 emissions

On-line analysers are also widely used for coal, notably in thermal power plants, mines, gasification plants and sometimes in coke plants where measuring the chemical composition of the coal is indispensable for the process.

With its electrical neutron source and the PFTNA technology, the Coal CNA made by SODERN is the only analyser on the market capable of directly measuring on-line and in real time all the major elements of coal, including carbon and oxygen.

Through this comprehensive elemental analysis, the coal CNA can define the main characteristics of the coal including total ash, calorific value (BTU), ash viscosity, volatile elements, etc

Unlike Cf252 analysers, the coal CNA can be installed directly on the main conveyor belt as its measurement is not affected by coal density variations and because it can analyse all types of coal.

The coal CNA is mainly used for the following applications:

· coal quality control

· managing pre-homogenisation stockpiles

· optimising coal blends to take advantage of lower costs while complying with the required quality levels

· continuous adjustment of boiler settings according to the characteristics of the coal

The robust Minerals CNA produced by SODERN and featuring PFTNA technology is making its way into the mining industry for the analysis of nickel, copper and iron, in the aim of improving processing efficiency and profitability.

The minerals CNA can be used for:

· controlling the quality of inputs

· stockpile optimisation and modelling before blending

· sorting minerals according to content

· adjusting the amount of acid required for the hydrometallurgical process

· adjusting the crushers

· controlling the basicity ratio for the pyrometallurgical process

These are but a few of the numerous advantages offered by the Minerals CNA in the mining process.

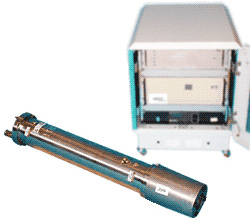

DOWNHOLE ANALYSER

This method of analysis is a major breakthrough on the conventional core sampling method, which requires the laboratory analysis of thousands of samples. The in-situ analysis obtained with this probe will do away with the costly operations involved in the coring, transport and preparation of samples. Moreover, the analysis will be much more accurate and will be available in real time.

For its analyses, the probe uses the PFTNA (Pulsed Fast & Thermal Neutron Activation) method. To avoid the use of a radioactive isotopic source, which is dangerous and prohibited for underground analysis operations, SODERN's probe is based on the use of an electrical source which poses no radiological risk for the environment in the event of loss of the tool in the borehole. The neutron tube, initially designed for oil exploration at great depths, has been specially optimised for reliability and durability in a confined environment. The detection unit consists of a new-generation inorganic scintillator which is particularly resistant to temperature fluctuations and provides a spectral resolution two to three times that of standard scintillators.

NEUTRON INSTRUMENTATION AND SPARE PARTS

GENIE 16 GT

has been especially designed for laboratory purposes.

The main features of this neutron generator are its highly reliable tube which reaches an unsurpassed lifetime while still being easy to use with Windows- based user-friendly software.

GENIE 35 Neutron Generator is a new neutron generator emitting up to 1.10+10 n/s in D-T version.

There is no doubt that this is the best trade-off between neutron output and cost.

Technical specifications and competitive advantages of all those generators are available by clicking on the appropriate icon.

Technical assistance and maintenance service contracts can be provided upon request.

SEALED NEUTRON TUBE

The Sodilog tube has been especially designed for oil logging pulsed neutron tools. The tube reliability has been significantly enhanced through a unique combinaison of ceramic technology and equimolecular loading of the deuterium and tritium gases, making it also very resilient to high temperature operations.

The Sodilog thus exhibits a long lifetime through this added sturdiness and can consequently be used for a wide range of application at a low cost of ownership. The Sodilog tube can be seamlessly used with Sodern neutron generator as well as with any customer in house equipement.

The Sodilog tube can be ordered in any quantity.

NEUTRON TARGET

A neutron target consists of a metallic substrate on which a thin layer of metal is deposited. This deposit is impregnated with deuterium or tritium or a mixture of both gases.

Targets are used in particle accelerators or neutron tubes to generate fast neutrons. The energy of neutrons depends on the reaction between an incident accelerated particle and tritium or deuterium trapped in the target.

Thermo Fisher Scientific | Diteco | Dosch | Hoffer | Airtek Saimo | Tectron

Master Mag | Igs | Titan | Gea Phe | Inox | Centec | Sodern